AI is transforming inventory risk management by helping businesses predict demand, manage supply chain disruptions, and reduce financial losses. Using tools like machine learning and predictive analytics, companies can make smarter decisions about stock levels, supplier reliability, and order timing. Here's what you need to know:

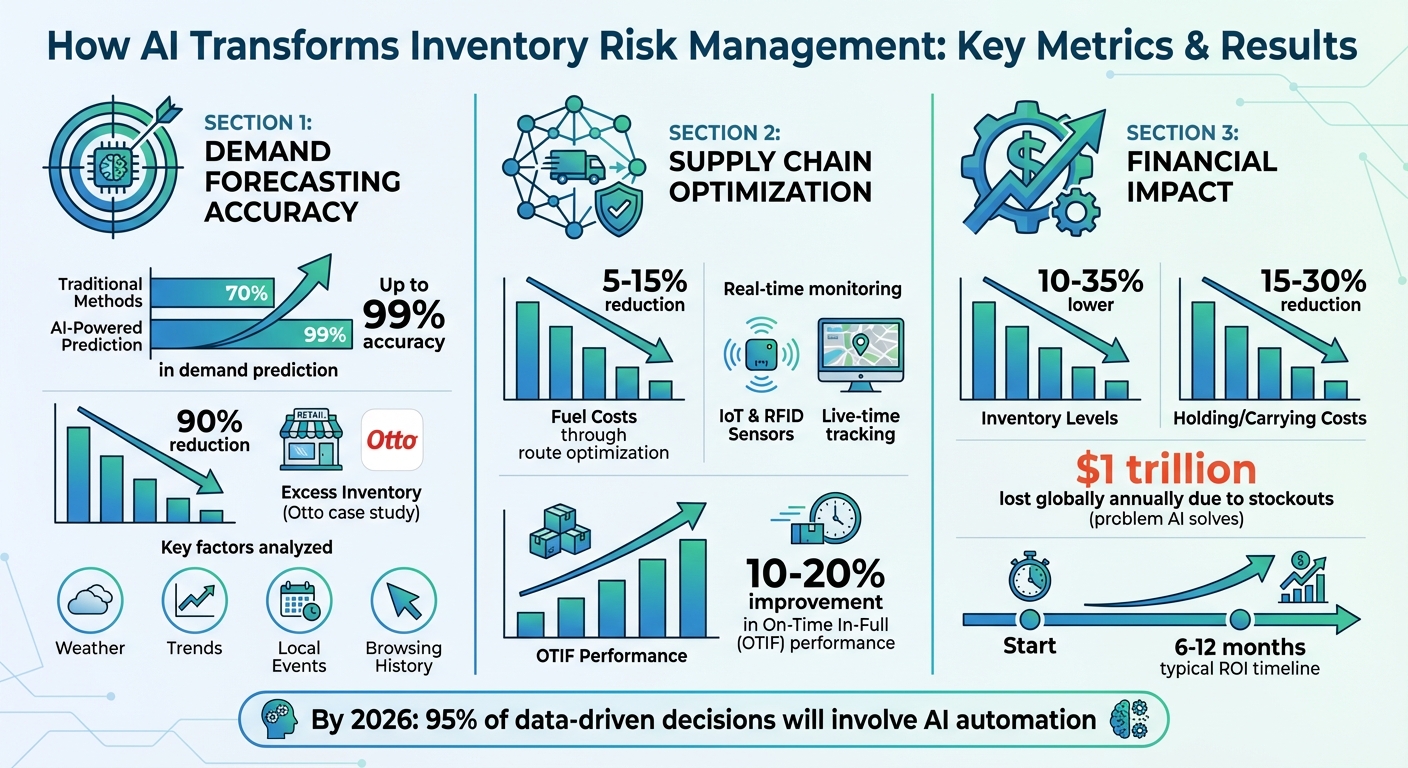

- Demand Forecasting: AI models analyze variables like weather, trends, and events to predict demand with up to 99% accuracy. Companies like Amazon and Otto use these systems to reduce stockouts and excess inventory.

- Supply Chain Management: AI improves supplier reliability predictions, optimizes delivery routes, and tracks inventory in real-time, reducing delays and costs.

- Financial Impact: Businesses using AI report 10–35% lower inventory levels, 15–30% reduced holding costs, and faster ROI (6–12 months).

AI Impact on Inventory Management: Key Statistics and ROI Metrics

From Guesswork to Guidance: AI Powered Inventory Management

Main Challenges in Inventory Risk Management

Managing inventory risks means tackling three closely linked issues: predicting customer demand, handling supply chain disruptions, and safeguarding financial performance. Each of these hurdles can trigger operational hiccups and eat into profits. Together, they highlight where AI can step in to improve forecasting, streamline supply chain operations, and strengthen financial management.

Demand Forecasting and Uncertainty

Getting customer demand predictions right is no small feat. Miss the mark, and you could end up with either empty shelves or piles of unsold stock, both of which hurt your bottom line. Seasonal spikes like Black Friday, viral social media trends, and fast-changing consumer preferences all add to the unpredictability. Companies relying on outdated, manual forecasting methods often find themselves scrambling to react.

Supply Chain Variability

Supply chain disruptions - think supplier delays or transport strikes - make it tough to keep inventory at the right levels. While diversifying suppliers can reduce risks and avoid single points of failure, that's only part of the solution. Poor coordination between warehouse systems and sales channels can lead to overselling or missed opportunities, forcing inventory teams to waste time on manual fixes instead of focusing on long-term strategies.

Financial Implications

When demand forecasting and supply chain issues collide, the financial fallout can be severe. Globally, businesses lose around $1 trillion every year because of out-of-stock items. Understocking leads to immediate revenue losses and can drive customers straight to competitors. On the flip side, overstocking ties up cash that could be better spent on growth initiatives like marketing or product development. Additional costs - such as high warehousing fees, insurance premiums, rushed shipping, and even disposal of unsold goods - further chip away at profits. As Zhaoyang Larry Jin explains:

Holding excess inventory further complicates operations and can lock up millions of dollars of capital that could be otherwise deployed

. Over time, these inefficiencies can shrink profit margins and leave businesses more exposed to market changes.

How AI Reduces Inventory Risks

AI steps in to tackle common inventory challenges like forecasting errors, supply chain hiccups, and financial losses by analyzing real-time data that traditional systems often miss. Instead of reacting to problems after they occur, AI anticipates and addresses them ahead of time, giving businesses an edge in managing stock and protecting profits. Let’s look at how AI improves demand forecasting, streamlines supply chain operations, and safeguards financial outcomes.

Better Demand Forecasting with AI

AI-powered models like Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks dive deep into sales data to uncover patterns influenced by variables like weather and local events. Take Starbucks as an example: they use LSTM networks to predict demand for beverages and snacks by factoring in weather conditions and neighborhood events, ensuring they’re ready for demand surges. Similarly, Amazon analyzes browsing history and seasonal trends to predict purchases, strategically positioning goods in nearby distribution centers to cut delivery times and avoid stockouts. Otto, a German e-commerce retailer, has taken this a step further - its AI-driven system forecasts demand so accurately that it pre-stocks inventory without human input, slashing excess inventory by 90%. These advancements directly address the uncertainties that often plague traditional forecasting methods.

Supply Chain Optimization

AI enhances supply chain efficiency by predicting supplier reliability and delivery times based on historical data, helping businesses spot potential delays or quality issues before they escalate. Real-time monitoring of inventory through IoT and RFID sensors allows for immediate adjustments to production and distribution schedules. Additionally, route optimization algorithms evaluate traffic, vehicle capacity, and driver availability to reroute shipments on the fly, cutting delays and reducing fuel costs by 5–15%. For instance, National Grid in the UK uses Google’s DeepMind platform to integrate weather data into its energy distribution forecasting, achieving highly accurate resource allocation.

Financial Risk Reduction

AI takes a dynamic approach to inventory management, adjusting reorder parameters based on variables like lead times and demand fluctuations, rather than relying on static rules. This method, known as stochastic optimization, can lower inventory levels by 10–35%. Companies using AI-driven inventory systems often see a 15–30% drop in carrying costs and a 10–20% boost in On-Time In-Full (OTIF) performance. Multi-Echelon Inventory Optimization (MEIO) further helps businesses fine-tune stock levels, freeing up working capital and reducing markdowns on unsold items. Impressively, most businesses recover their investment in AI within just 6 to 12 months.

sbb-itb-d1a6c90

Implementing AI in Inventory Management

Data Requirements and Governance

For AI models to deliver accurate predictions, they need reliable and up-to-date data. Before diving into AI adoption, it's crucial to consolidate inventory, sales, forecasting, and bill of materials data into a unified system. Breaking down data silos is essential, and incorporating sensor data can provide real-time insights into stock levels and supply chain dynamics.

Effective governance revolves around four key elements: AI vision (aligning AI with strategic goals), value (removing internal obstacles), risks (addressing regulatory and reputational challenges), and adoption (focusing on practical use cases). Transparency is non-negotiable - AI systems should clearly explain the factors behind their recommendations, such as supplier lead times or demand variability. A human-in-the-loop approach allows managers to review AI-generated reorder suggestions, offering the flexibility to approve, adjust, or reject them. This not only builds trust but also ensures managers retain oversight.

Once the foundation of solid data and governance is laid, the next step is selecting AI tools that align with your needs.

Selecting the Right AI Tools

The first step is to audit your processes and identify small, automatable decisions, such as determining the timing of orders. Choose tools that integrate seamlessly with your current Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) systems, enabling smooth data sharing and workflow continuity. Opt for solutions that allow "what-if" scenario testing to assess how changes might impact your business.

To ensure success, define performance metrics early for each AI use case - this helps track measurable ROI. For smaller businesses, starting with "Everyday AI" solutions can improve routine operations without overwhelming complexity. With projections suggesting that 95% of data-driven decisions will involve some degree of automation by 2026, it's wise to select tools that can scale as your business grows.

Using Curated Directories Like BizBot

Once you've identified compatible AI tools, curated directories like BizBot can simplify the selection process further. These directories help narrow down options, reducing the risk of decision fatigue - a significant advantage considering that 42% of small business owners cite lack of expertise as a major hurdle to AI adoption.

BizBot's directory offers a wide range of management tools and software that integrate effortlessly with platforms like Shopify, QuickBooks, and Xero. This ensures you avoid overspending on complex enterprise-grade solutions that may not suit your business needs. By leveraging such directories, businesses can make more informed and efficient decisions when implementing AI.

Conclusion

AI is revolutionizing inventory risk management, turning what was once a game of guesswork into a precise, data-driven process. By tackling major challenges like unpredictable demand and supply chain fluctuations, AI empowers businesses to fine-tune stock levels while still meeting service goals. Companies leveraging AI-based stochastic optimization have already seen tangible results: lower inventory levels, reduced shipping costs, and improved On-Time In-Full performance.

These outcomes highlight how AI is reshaping traditional systems. Instead of relying on outdated MRP methods, AI introduces real-time monitoring, scenario simulations, and automated replenishment strategies. As Upendra K Kar from the University of Pittsburgh puts it:

AI has been proved to become an extension of our brain, expanding our cognitive abilities to levels that we never thought would be possible

. This expanded cognitive capability translates to faster and more accurate inventory decisions. For instance, generative AI can reduce decision-making time from several days to just minutes.

Looking ahead, advanced techniques like Deep Reinforcement Learning hold the potential to manage vast and intricate supply chains, even though implementation hurdles remain. Emerging concepts such as Supply Chain Digital Twins and agentic AI are paving the way for systems that can operate with minimal human oversight. Additionally, quantum computing could eventually address optimization challenges that current AI systems struggle to solve. These innovations hint at a future where AI-driven supply chain management becomes even more efficient and autonomous.

To make the most of these advancements, businesses should focus on strong data governance, start with smaller, manageable use cases, and explore curated directories like BizBot for integrated tools. AI has moved past its theoretical phase, delivering measurable ROI today while continuing to evolve.

The future of inventory management isn’t about replacing human judgment entirely - it’s about enhancing it. As supply chains grow more complex, AI will shift from being a competitive advantage to an essential tool, completing the transition from manual forecasting to AI-supported decision-making.

FAQs

How does AI enhance demand forecasting for inventory management?

AI is transforming demand forecasting by applying advanced machine learning to sift through massive amounts of data. It doesn't just stop at historical sales figures and market trends - it even processes unstructured data like customer reviews and social media chatter. This allows AI to uncover intricate demand patterns and refine predictions almost instantly, delivering forecasts with greater precision.

With AI, businesses can strike a better balance in their inventory management. It minimizes the risks of overstocking or running out of stock, ensures inventory levels are optimized, and helps companies adapt quickly to market shifts. The outcome? Streamlined operations and smarter inventory decisions.

What financial advantages does AI bring to inventory management?

AI-powered inventory management can transform how businesses handle their stock, delivering measurable financial benefits. With smarter demand forecasting and enhanced supply chain efficiency, companies can cut holding costs by 10%–20% and trim shipping expenses by 5%–15%.

By reducing stockouts and avoiding overstocking, businesses can free up cash flow and see a boost in profitability. Beyond just streamlining operations, these tools empower businesses to make smarter, data-backed decisions about inventory levels, ensuring resources are used effectively.

How can businesses start using AI to improve inventory management?

Businesses can start by getting their data in order. This means gathering historical sales records, supplier lead times, and any relevant sensor data, then cleaning and centralizing it to ensure the information is accurate and ready for AI models. To ease into the process, companies can launch a small pilot project. Using AI-powered forecasting tools, they can predict demand for specific products and compare the results against traditional forecasting methods. If the pilot shows better accuracy, that’s a clear signal to expand the approach.

From there, businesses can bring AI into their daily operations. Tools that automate inventory decisions - like adjusting reorder points or managing safety stock levels - can be integrated into existing systems, making order placement smoother and more efficient. Real-time dashboards can also play a crucial role, enabling managers to quickly react to unexpected demand spikes or potential stock shortages.

For businesses looking to simplify this transition, platforms like BizBot can be a great resource. BizBot provides a curated directory of AI-driven inventory management tools, helping companies find solutions that fit their budgets and specific needs. By taking these steps, businesses can cut down on holding costs, enhance service levels, and make smarter inventory decisions - all with minimal risk.