Integrating your systems with a third-party logistics (3PL) provider's warehouse management system (WMS) ensures smoother inventory updates, order processing, and shipment tracking. Without proper integration, businesses risk delays, errors, and inventory mismatches that harm customer trust.

Here’s what you need to know:

- Challenges: System compatibility, data mapping errors, and security risks can disrupt operations, inflate costs, and expose sensitive data.

- Solutions:

- Use flexible integration methods like REST APIs for real-time updates and SFTP for batch processes.

- Standardize data formats (e.g., ANSI X12, XML) and automate validation to reduce errors.

- Strengthen security with encrypted data transfer, role-based access, and multi-factor authentication.

- Key Metrics to Monitor:

- Dock-to-Stock Time: Aim for under 24 hours.

- Inventory Accuracy: Target over 99.5%.

- Order Accuracy: Exceed 99.9%.

What should I connect my 3PL to? eCommerce or Inventory/ERP System

sbb-itb-d1a6c90

Common Problems in Vendor Integration

Connecting vendors to your 3PL WMS can bring a host of challenges that disrupt operations and inflate costs. Three key issues often arise: technology compatibility, data mapping errors, and security risks.

Technology and System Compatibility Problems

Many third-party WMS platforms are "interfaced" rather than fully integrated, which means they operate using separate databases and servers, often requiring business administration tools to manage the resulting silos. This setup often requires batch exports, middleware, or custom development - essentially duplicating processes. Older or heavily customized systems can lack integration hooks altogether, leading to expensive customizations.

"Sometimes a client's last data integration effort was so traumatic - so rigid in its formatting requirements - that the client is afraid to expand or improve their data visibility tools".

Without real-time syncing, gaps in inventory and order data emerge, forcing teams to manually reconcile discrepancies. While 94% of 3PL providers offer Electronic Data Interchange (EDI) integration, mismatched protocols or APIs still cause headaches when trying to link different systems.

On top of technical mismatches, differences in data structures create even more complications.

Data Errors and Mapping Difficulties

Incorrect data mapping can snowball into a series of problems. When systems use inconsistent schemas or naming conventions for fields like SKUs, UPCs, or batch numbers, you could end up with mis-picks, shipping errors, or inaccurate inventory counts. If your vendor and 3PL WMS update their data at different intervals, products might appear available for sale even after they've shipped.

These mapping issues also lead to billing errors that can damage trust. Disjointed data makes it harder to track key performance indicators, often requiring manual reconciliation to fill in the gaps - an added strain on resources.

These data challenges not only disrupt daily operations but also introduce vulnerabilities that could be exploited.

Security Risks and Compliance Requirements

Every integration point in your system is a potential weak spot. If a vendor's APIs are outdated or insecure, your entire network could be at risk. Since 2020, supply chain–focused cyberattacks have quadrupled, with the average cost of a data breach reaching $4.45 million in 2023.

Ransomware attacks targeting logistics networks can do more than steal data - they can shut down operations entirely, leading to canceled orders and reputational damage.

"In today's threat environment, a breach in your 3PL's network could become your reputation problem".

Compliance with regulations like GDPR and CCPA adds another layer of complexity. Full traceability and strict data governance are essential when working with integrated partners. Human error also plays a role; untrained warehouse staff may fall victim to phishing scams, further exposing your network to threats. These security gaps undermine the reliability of what should be seamless vendor integration.

Proven Methods for Vendor Integration

Tackling integration challenges means finding the right balance between flexibility, precision, and security. By addressing compatibility, mapping, and security concerns head-on, you can transform vendor connections into a real asset for your business. The key lies in using smarter business banking tools and integration architectures, standardized data formats, and robust access controls.

Building Flexible Integration Systems

A dual-protocol approach works wonders: use REST over HTTPS for real-time updates like order tracking, and SFTP for nightly batch processes such as inventory reconciliations. This method accommodates vendors with modern APIs while supporting those still reliant on flat file exports.

For real-time stock tracking, model your third-party logistics (3PL) provider as an inventory organization within your ERP system. To avoid hard-coding logic into your warehouse management system (WMS), consider using an integration layer like Oracle Integration Cloud. This layer can handle custom mappings and data transformations with ease.

Security is non-negotiable. Implement strong authentication protocols such as OAuth, SAML, or JWT to handle high-volume integrations securely. Designate a single source of truth for each data entity - whether it’s items, vendors, or purchase orders - and avoid unnecessary bidirectional data flows. This approach keeps your data consistent and reduces errors.

Creating Standard Data Formats and Validation Rules

Standardizing data starts with using industry-recognized formats like UN/EDIFACT and ANSI X12 for critical documents such as Advanced Shipping Notices (ASNs) and purchase orders. For vendors unable to support EDI, offer alternatives like XML templates with XSD schemas or Excel/flat file templates to simplify mapping.

Automated validation is your safety net. For example, web services can check XML payloads against predefined XSD schemas during transmission to catch errors like mismatched SKUs or incorrect batch numbers before they disrupt your system. Applying business rules at the integration layer ensures only clean, relevant data reaches its destination.

"Integrations can become too complex - too convoluted... The FIDELITONE integration hub is all about making the process as easy as possible for the client".

Clearly define all business requirements and data touchpoints upfront, from inventory adjustments to exception handling and nightly reconciliations. Regularly auditing your data pipelines can help catch issues like drifting stock counts or missing products before they escalate.

Once your data is standardized, the next priority is securing every access point.

Strengthening Security and Access Controls

A secure vendor integration framework relies on multiple layers of protection. Start by using IAM roles and temporary credentials instead of long-term access keys to reduce the risk of unauthorized access. Follow the principle of least privilege, granting third parties only the permissions they need - such as access to specific inventory organizations or transaction types. Incorporating universally unique identifiers (UUIDs) in trust policies can help prevent unauthorized impersonation.

Encrypt data during transit using HTTPS or SFTP, and enforce multi-factor authentication for all third-party users. Comprehensive activity logging, paired with automated alerts for suspicious behavior like failed login attempts or unusual access patterns, allows for swift incident response. Regularly recertifying third-party access ensures permissions stay aligned with current business needs.

To minimize direct exposure to the internet, establish private connections between your supply chain systems and partner environments. Apply granular security rules at the inventory organization level to control what users can create, read, update, or delete, ensuring they only access data relevant to their roles. When working with third-party SaaS providers for your WMS, carefully review their shared responsibility model to clarify which security measures they handle and which ones are your responsibility.

Tracking and Improving Integration Performance

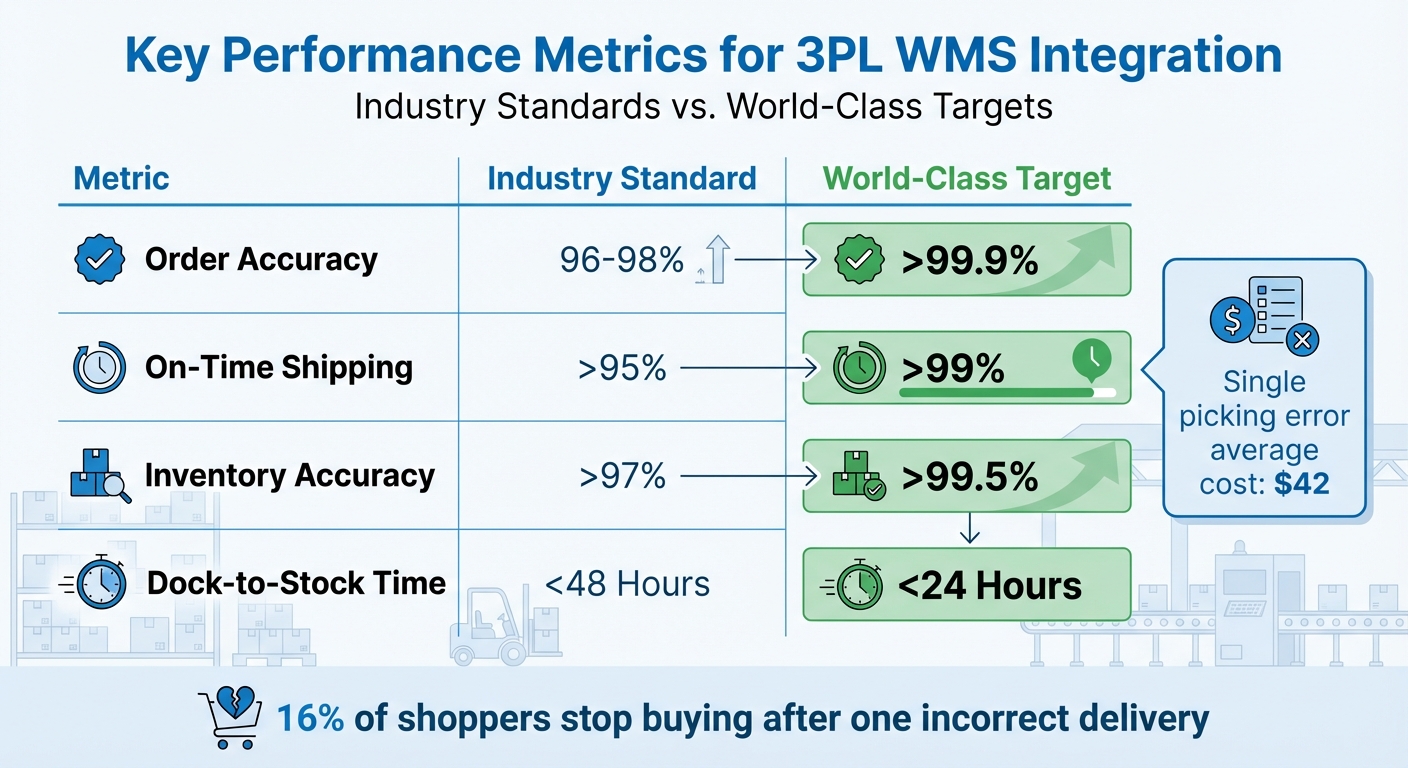

3PL WMS Integration Performance Metrics: Industry Standards vs World-Class Targets

Keeping an eye on real-time data can completely change how you handle issues. Instead of waiting for monthly reports, you can catch problems as they happen - before they affect your customers. This matters because 16% of shoppers will stop buying from a retailer after just one incorrect delivery, and 69% are unlikely to return if their order is late.

Real-Time Performance Tracking

Once your integration is up and running, tracking its performance becomes a top priority. Monitoring key metrics gives you a clear picture of how well the integration is functioning. For instance, Dock-to-Stock time measures how quickly incoming goods are ready for sale in your warehouse management system (WMS). The industry standard is under 48 hours, but top performers aim for less than 24 hours. Another critical metric is Inventory Accuracy Rate, which should exceed 99.5% to avoid stock discrepancies that can lead to stockouts or over-ordering. Similarly, Order Accuracy - the percentage of error-free shipments - should surpass 99.9%, especially since a single picking error costs, on average, $42.

Setting up alerts for issues like threshold breaches or data flow failures ensures that inventory stays aligned across all channels, avoiding overselling. Dashboards can help you track metrics like On-Time Shipping (measuring warehouse efficiency) and Cost Per Unit Shipped, providing insights into financial performance and areas where you can save money.

| Metric | Industry Standard | World-Class Target |

|---|---|---|

| Order Accuracy | 96-98% | >99.9% |

| On-Time Shipping | >95% | >99% |

| Inventory Accuracy | >97% | >99.5% |

| Dock-to-Stock Time | <48 Hours | <24 Hours |

Improving Processes Through Vendor Feedback

Tracking metrics is just the start - refining processes is where the real improvements happen. Establish a governance cadence by scheduling weekly meetings to address immediate issues, monthly sessions to review KPIs, and quarterly reviews for strategic planning. When metrics fall short, use the "5 Whys" technique to dig into the root cause. For example, a delay might stem from an understaffed receiving dock or a mapping error in the system.

To take it further, give vendors access to real-time dashboards showing order statuses, inventory levels, and error rates. This transparency turns mistakes into opportunities for collaboration instead of finger-pointing. For example, NorthRiver Fulfillment improved operational efficiency by 30% and cut order processing time by 20% by treating errors as chances to redesign workflows rather than isolated problems.

When issues arise, implement Corrective Action Plans (CAPs) that outline the problem, solution, responsible party, and timeline. Prioritize KPIs based on your business model. A luxury brand might focus more on Order Accuracy, while a budget-focused company could prioritize Cost Per Unit.

"Managing 3PL performance is an ongoing system, not a one-time task".

Conclusion

Integrating vendors effectively into your 3PL WMS can give your business a serious edge, directly impacting your bottom line. By addressing compatibility issues, standardizing data formats, and prioritizing strong security measures from the start, logistics can shift from being a cost burden to becoming a powerful strategic tool. In fact, 82% of companies report that their 3PL partners help them deliver better customer service, and smart integration can turn fixed logistics costs into more adaptable, variable expenses.

The growing logistics automation market highlights this trend, with projections climbing from over $88 billion in 2025 to nearly $213 billion by 2032. Companies that invest in solid integration strategies are better equipped to scale efficiently, avoid costly errors, and reduce reliance on manual processes that can eat into profit margins.

"The deeper the integration - that is, the more thorough the act of connecting systems, automating processes, and syncing data in real time - the greater the benefits." – International Journal of Academic Management Science Research

Industry research emphasizes the shift from transactional vendor relationships to strategic partnerships, showcasing how integration can truly transform operations. By focusing on proven, quick-to-implement methods, businesses can turn vendor connections into a competitive strength. This approach not only solves operational challenges but also drives measurable growth, making vendor relationships a cornerstone of success.

FAQs

What are the key security risks when integrating vendors with 3PL WMS systems?

Integrating vendors with 3PL Warehouse Management Systems (WMS) can bring convenience, but it also comes with its share of security risks if not handled carefully. One of the biggest concerns lies in the APIs used for these integrations. If these interfaces aren’t safeguarded, they can become a gateway for cybercriminals. This could result in data breaches, operational hiccups, or even the theft of sensitive information.

Another area to watch out for is third-party access management. Vendors or external consultants who have access to your systems can unintentionally serve as weak links. Risks here include granting excessive permissions, failing to monitor access, or working with vendors who haven’t been thoroughly vetted. On top of that, insecure network communication - like unencrypted or unauthenticated data transfers - can leave your system vulnerable to interception or attacks such as man-in-the-middle exploits.

To stay ahead of these risks, it’s essential to prioritize a few key practices:

- Secure API connections with proper authentication and monitoring.

- Implement strict controls on who can access your systems and what they can do.

- Ensure all data transfers are encrypted and authenticated to prevent interception.

Taking these steps can go a long way in protecting your supply chain and keeping your operations running smoothly.

What are the best practices for ensuring data accuracy when integrating with a 3PL WMS?

To maintain precise data when working with a 3PL Warehouse Management System (WMS), it's crucial to prioritize automation and simplicity. Automating tasks like field value calculations or data transformations can help cut down on manual errors and ensure your data stays consistent. Keep your data mappings straightforward to avoid unnecessary discrepancies, while reserving complex processes for your main system, such as an ERP.

Make it a habit to regularly reconcile inventory data between your ERP and WMS. This step helps you catch and fix mismatches in inventory levels, serial numbers, or lot details before they become bigger issues. On top of that, enforce strict security rules to control access and prevent unauthorized changes, which plays a big role in preserving data accuracy.

By blending automation, frequent data reconciliation, and robust access controls, you can enhance the accuracy and dependability of your 3PL WMS integration.

What are the best practices for tracking vendor integration performance in a 3PL WMS?

To keep a close eye on how well vendor integration performs in a 3PL Warehouse Management System (WMS), it's crucial to start with clearly defined key performance indicators (KPIs) that align with your business goals. Metrics like inventory accuracy, order processing times, and shipment reliability are great benchmarks for measuring success. Regularly reviewing these KPIs using performance scorecards can help you spot potential issues early and address them before they escalate.

Another important factor is real-time data monitoring. Tools like IoT sensors and RFID technology can provide accurate tracking and ensure a smooth flow of data across the system. Additionally, continuous testing - such as performance and load testing - helps maintain the system’s responsiveness and reliability. When these strategies are combined, businesses can enhance supply chain visibility, reduce errors, and keep their integrations running smoothly.